What are SIP’s

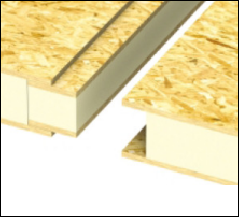

SIP's (Structurally Insulated Panel) are a highly sustainable sandwich construction

comprising two layers of sheet material bonded to a foam insulation core. They have

hardly any internal studs within the panels and rely on the bond between the foam

and the two layers of sheet material to form a load-bearing unit (though there may

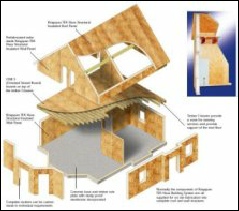

be studs at corners and around some openings). SIP panels are used in the same way

as timber- or steel-framed panels. One advantage of SIP panels is that the insulation

layer is more continuous than in normal framed panels. This leads to better thermal

performance for a given thickness of panel because of the absence of thermal bridges

associated with studs.

The two layers of sheet material can be of a variety of materials; oriented strand

board and cement-based boards are fairly common. The rigid foam core will usually

be expanded polystyrene, polyurethane or polyisocyanurate.

Advantages of SIP's

- Highly sustainable construction method

- Faster completion times compared to many other construction methods

- Superior thermal performance compared to other methods on like for like thickness

- Exterior cladding and first fix internal works can be installed at the same time

- Superior air tightness without out the need for air barriers

- Very low on site waste